Applicance

Applicance solutions

Modular laser systems for every applicance workflow

From cutting flat panels to welding curved stainless shells and refreshing tooling, EASY LASER integrates self-developed controllers, self-hosted fonts, and the brand color system already used throughout this site to present a consistent customer experience.

High-energy CO2 beams for organic materials

Laser cutting machine—CO2 laser

Deliver smooth edges on acrylic, wood, textiles, and composite boards with an optimized optical path, enclosed safety shell, and automatic focusing mirror mount.

-

01

Signage & advertising

Large-format acrylic, MDF, and PVC boards for retail fixtures.

-

02

Textile creative cutting

Digitized patterns for felt, cotton, denim, and synthetic fabrics.

-

03

Woodcraft & giftware

Precise engraving for toys, ornaments, and cultural creations.

-

04

Acrylic crafts & DIY

Batch production of décor, puzzles, and educational kits.

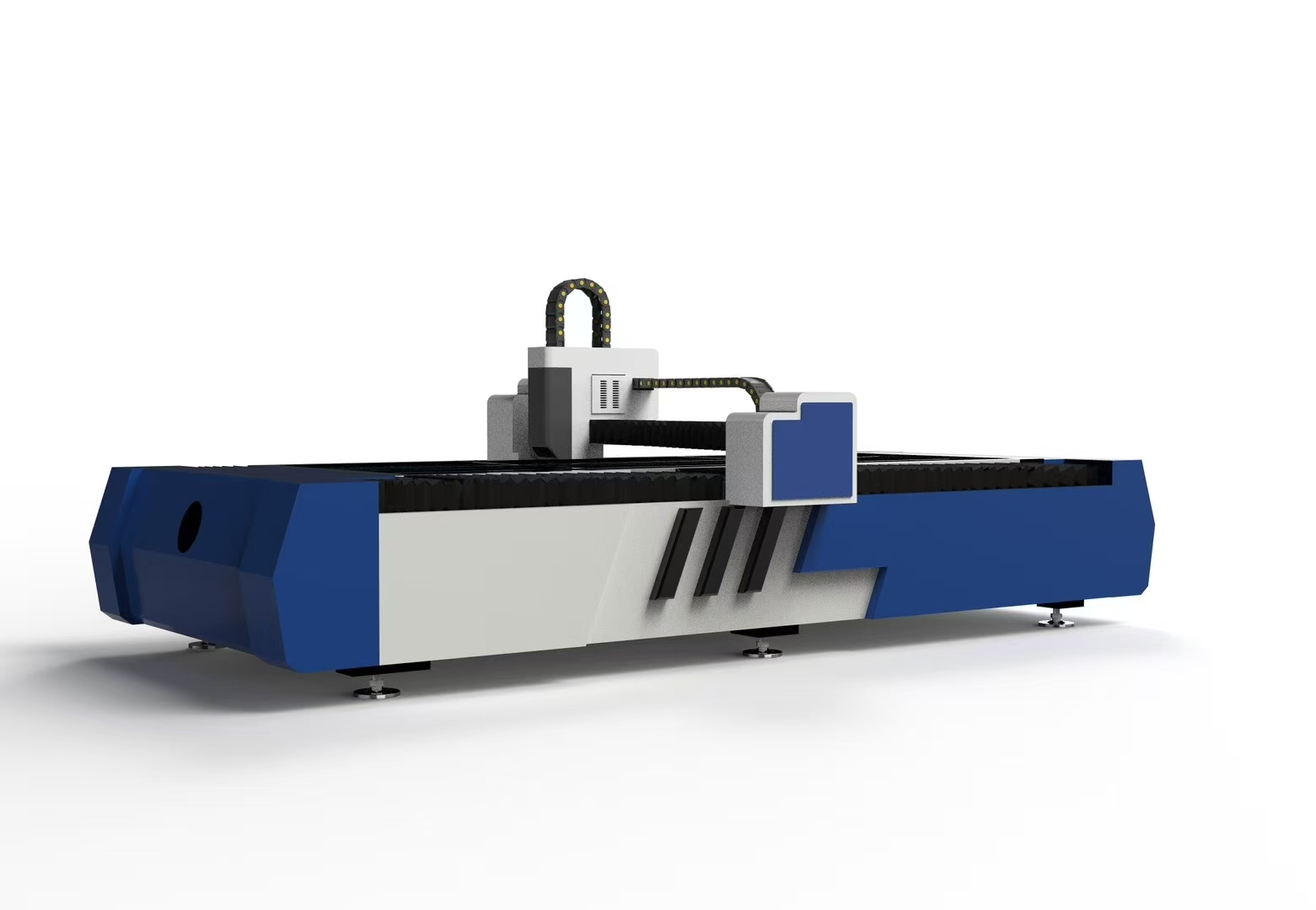

Metal fabrication powerhouse

Laser cutting machine—Fiber laser

Fiber sources with beam combiners achieve micron-level kerf, fast piercing, and high reflectivity protection for ferrous and non-ferrous metals.

-

01

Sheet metal processing

Cabinet doors, chassis, and ventilation ducts.

-

02

Kitchenware manufacturing

Food-grade stainless steel cookware with burr-free edges.

-

03

Automotive supply chain

Precision brackets, seat components, and EV battery plates.

-

04

Medical fabrication

Stents, orthotics, and cleanroom fixtures.

Precision seams with less post-processing

Laser welding machine

Handheld, robotic, and gantry welding options deliver mirror-finish seams on stainless steel, aluminum, brass, and complex assemblies with low heat distortion.

-

01

3C electronics

Aluminum enclosures, laptop stands, smart wearable frames.

-

02

Additive industry

Repair and finishing of printed metal structures.

-

03

Furniture & décor

Thin-wall tube furniture with mirror seams.

-

04

Hardware custom shops

Small-batch connectors and fixtures.

Non-contact cleaning & surface activation

Laser cleaning machine

Pulse widths down to nanoseconds strip rust, paint, and oil without damaging base materials, keeping molds, dies, and pipelines at peak efficiency.

-

01

Injection equipment maintenance

Mold polishing and residue removal.

-

02

Infrastructure refurbishing

Bridge guard rails, rail tracks, and ship hulls.

-

03

Aerospace & power

Engine overhaul, turbine blade cleaning, wire harness prep.

-

04

Precision manufacturing

Surface activation before welding or coating.