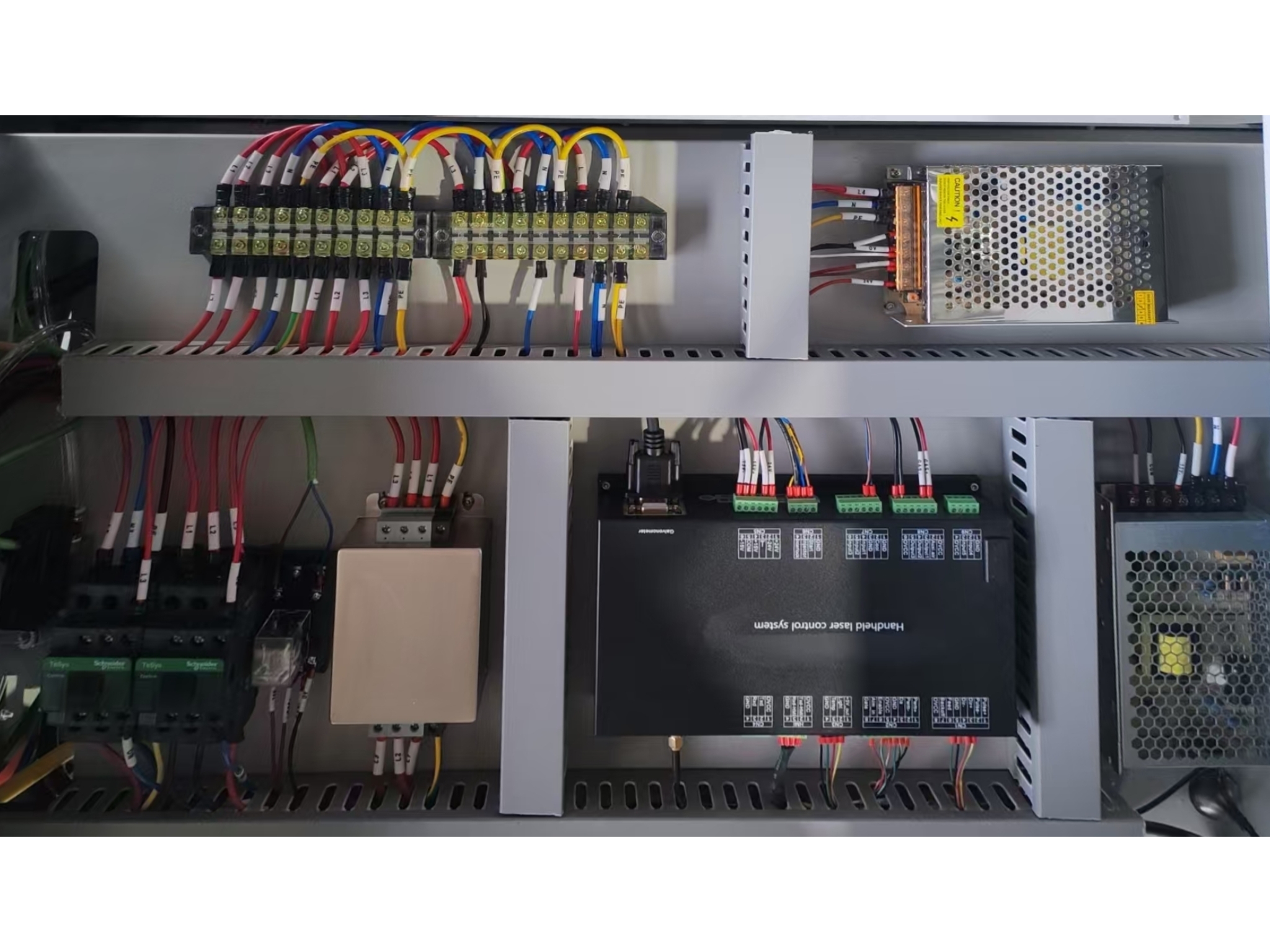

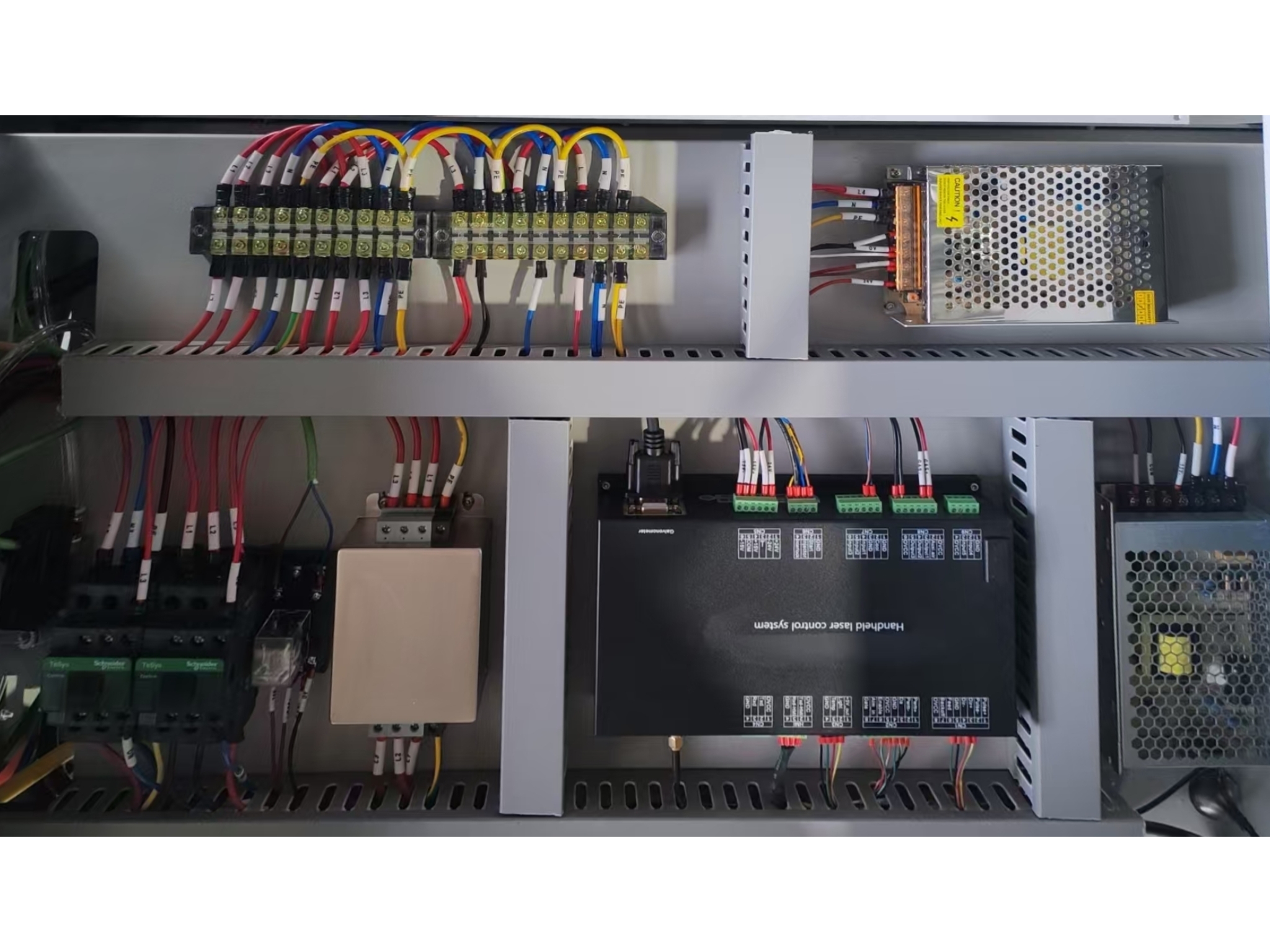

Circuit assembly conforming to EU standards

The transparent circuit boards in the machine comply with IEC 61439-1&2 standards, ensuring the safety and reliability of low-voltage switchgear and control equipment components.

1000W 1500W 2000W 3000W Laser Cleaning Machine

The transparent circuit boards in the machine comply with IEC 61439-1&2 standards, ensuring the safety and reliability of low-voltage switchgear and control equipment components.

The continuous wave laser cleaning machine uses a water cooling system to ensure stability and efficiency, effectively dissipate heat, and prevent overheating.

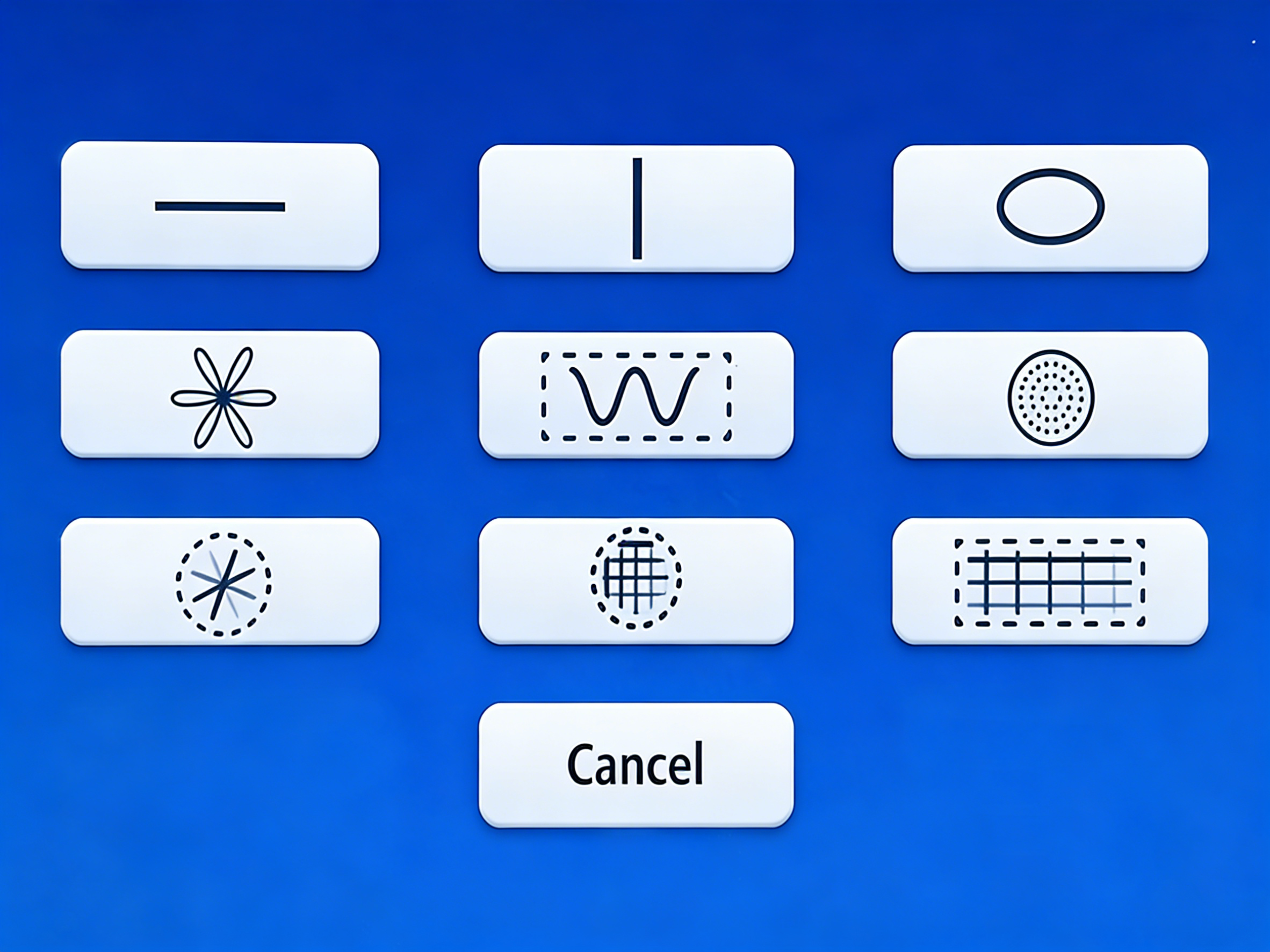

Line A / Line B / Vertical line / Ellipse / Point-filled circle / Wave pattern / Rotated-filled circle / Straight-filled rectangle / Line-filled circle

Laser cleaning machine supports 24 languages: Chinese / English / Russian / Ukrainian / Deutsch / Japanese / Korean / French and so on

| Model Number | Laser Source | Laser Power | Fiber Optic Cable Length | Cleaning Speed | Cooling Method | Warranty Period | Operating Ambient Temperature | Laser type |

|---|---|---|---|---|---|---|---|---|

| WWSH-SW1000 | aycus / MAX / BWT | 1000W | 10M | ≤40 square meters/hour | Water cooling | 1 Year | 5-40℃ | Continuous laser |

| WWSH-SW1500 | Raycus / MAX / BWT | 1500W | 10M | ≤40 square meters/hour | Water cooling | 1 Year | 5-40℃ | Continuous laser |

| WWSH-SW2000 | Raycus / MAX / BWT | 2000W | 10M | ≤40 square meters/hour | Water cooling | 1 Year | 5-40℃ | Continuous laser |

| WWSH-SW3000 | Raycus / MAX / BWT | 3000W | 10M | ≤40 square meters/hour | Water cooling | 1 Year | 5-40℃ | Continuous laser |

| WWSH-KR-PC500 | Raycus / MAX / BWT | 500W | 10M | ≤40 square meters/hour | Water cooling | 1 Year | 5-40℃ | Pulsed laser |

| WWSH-KR-PC1000 | Raycus / MAX / BWT | 1000W | 10M | ≤40 square meters/hour | Water cooling | 1 Year | 5-40℃ | Pulsed laser |

| Customize | Customize | Customize | Customize | Customize | Customize | Customize | Customize | Customize |

Tell us your material, thickness and application — we'll recommend the best configuration and pricing.